If you want to know how to run electricity to a shed, you’ve come to the right place. This article provides a step-by-step guide so you can do it safely. You’ll also learn about the various tools and materials you need. And if you want a professional to do it for you, Tercero is perfect for you.

Does running electricity to a shed require a permit?

Yes, like any other electricity project, you will require a permit from your municipality. With a license, you can rest assured it is protected from unseen events such as fire due to wiring. Without it, insurance will not cover the property damage.

Likewise, potential buyers are likely to shy away if you put your property on sale without the shed’s permit. As such, your property loses value and, of course, potential buyers.

Besides, running electricity without a permit is a sure way to be at loggerheads with your neighbors. Imagine your neighbor calling your municipality asking if you can run electricity to your shed. You’ll end up having trouble with the authorities.

And as you’d expect, you are more likely to pay hefty fines and penalties. As such, you must obtain the relevant permits before moving forward with your project.

Tools and materials for running electricity to a shed

To successfully run electricity to your shed, you need the following tools:

- Shovel

- GFCI outlet

- PVC conduit

- UF-B electrical cable

- Tape measure

- Safety gear

- Cordless drill

- Wire strippers

- Pliers

- Circuit breakers for panel

- Sub-panel

- Receptacles, switches, and boxes

- Wires

Options for running power to a shed

Running electricity to your shed provides you with a wide array of options. These options depend on the shed’s location, distance from the main house, the ground, and others. Such factors, therefore, affect the cables you can use. Some of the most popular include:

Extension cord

An extension cord is arguably the most popular way to run electricity to a shed. While popular, it comes with its downsides. For example, it is incompatible with bad weather, especially during rainy and snowy days. It is also not permanent, meaning it can be affected by several elements.

Finally, unlike other options, it does not add value to your property. That said, it is cheap to install, simple to maintain, and you’ll not require a permit.

Cable above ground

While it is advisable to bury or string electricity cables overhead, you can still use the cable above-ground option. They are cheaper and easier to install and maintain. They are also safer than underground cables since they are sightlier. However, they are ideal for sheds far from the main house.

Some advantages of cable above ground are: it requires less digging, is a permanent power source, and can be used in different ground types. Conversely, you will need a permit, and you might require an electrician for connections.

Underground feeder cable

Also known as direct burial, it is intended to be buried in the ground. As you’d expect, the casing around the wire is thicker, protecting it from water and other elements. It also provides a better connection than the extension and above-ground options since it is not exposed to many weather elements.

It is easier to install an underground feeder cable than above ground. They are also cheap as they do not require a conduit. And if you have stable soil on your property, this is the perfect choice for you. Having said that, they are harder to replace and are susceptible to damage due to earth movement.

Underground conduit

Finally, you can use an underground conduit. It is a wire that runs in an enclosed PVC conduit, improving its safety. Generally, the tubing will run from the main house through a header or similar part and extend underground, straight to the shed. From here, it will run to the switch.

Using rigid metal conduit might be the best option if your property is in a high-traffic area. It is because metal is stronger and can withstand weather elements. Where bends are inevitable, using a flexible metal conduit is the better option since it can bend and curve without breaking.

The rigid metal conduit is the most expensive among the three as you will require several fittings to go through curves and bends. Using an underground pipe provides better protection and is easier to replace. Unfortunately, they are more expensive and time-consuming to install.

How to run electricity to a shed

Planning and preparation

Before running electricity to your shed, you need to ensure your electrical panel has enough space to run the wire to the shed. Generally, a small house with a 200A panel is ideal for running the wire. On the contrary, a 100A panel might not be enough.

If yours is a 100A panel, hire a reputable electrician to upgrade it to 200A. Once at 200A, it’s time to decide how much power the shed requires. It is dependent on the machines you’ll be operating. For peace of mind, overestimate the number of amps you will need.

Also, consider how the power will run from the panel to the shed. Will you use an underground conduit? Underground feeder cable? Perhaps an extension cord? As mentioned, the property’s distance, soil type, and landscape are huge determinants.

Plan the circuit

Once you plan the general layout, you should plan how many circuits the shed will have. While using a single electrical cable, you can use multiple circuits depending on the shed’s nature. As such, you’ll need a sub-panel.

It enables the use of multiple circuits up to the shed’s breaker capacity, meaning if you install a 60A circuit breaker, you can install up to three 20A circuits. You don’t need to use a sub-panel if you only require one circuit.

Also, consider the appliances you’ll be using in the shed. Ideally, most household appliances have a voltage of 120V. However, larger ones tend to have a 240 V rating. If you plan to use the latter, a sub-panel is a requirement.

Draw shed wiring diagram

It is a representation of how your electrical system will look like. It, therefore, allows you to identify opportunities and risks before laying down electrical cables. Thanks to the diagram, you can easily identify load amounts and amp ratings, meaning the circuits will not overload.

Besides, you can easily choose the most efficient route to install the wiring. And as you’d expect, you’ll identify where to install the sub-panel if you might need more circuits in the future.

Select the wires to use

Here, you need to identify the wire’s gauge to avoid overloading. Gauge is the thickness of the metal in the wire. A thicker gauge means a larger load. You can use this chart to identify the ideal gauge for your project.

We also recommend considering the voltage drop as the electricity runs to the shed. Ideally, a length of fewer than 100 feet will have an insignificant voltage drop and vice versa. You can use this calculator to determine the wire to use.

Choose a conduit

A conduit is a tubing through which the wire runs, ideally for added protection. It is, therefore, necessary for options such as cable above ground. It helps protect the wire from heat, water, and snow, among other elements.

The PVC conduit is ideal since it can bend around subtle curves. It is also cheaper and easy to cut, maintain, and replace. However, ensure it is 18” deep, as this is an NEC requirement. If you need extra protection, consider using the metallic conduit. It only needs to be 6” deep, making it ideal for rugged environments.

Dig the trench

Once you have your conduit, wire, sub-panel, and other materials, it is time to dig the trench. If you are using the PVC conduit, ensure it is 18”. For a metallic tube, let it be 6” deep. Once near the shed, you can run the wiring underneath it or run up the exterior wall and then through it.

If you are using a sub-panel, ensure to provide a grounding rod. Also, check with your municipality if there’s a gas pipe running near the trench.

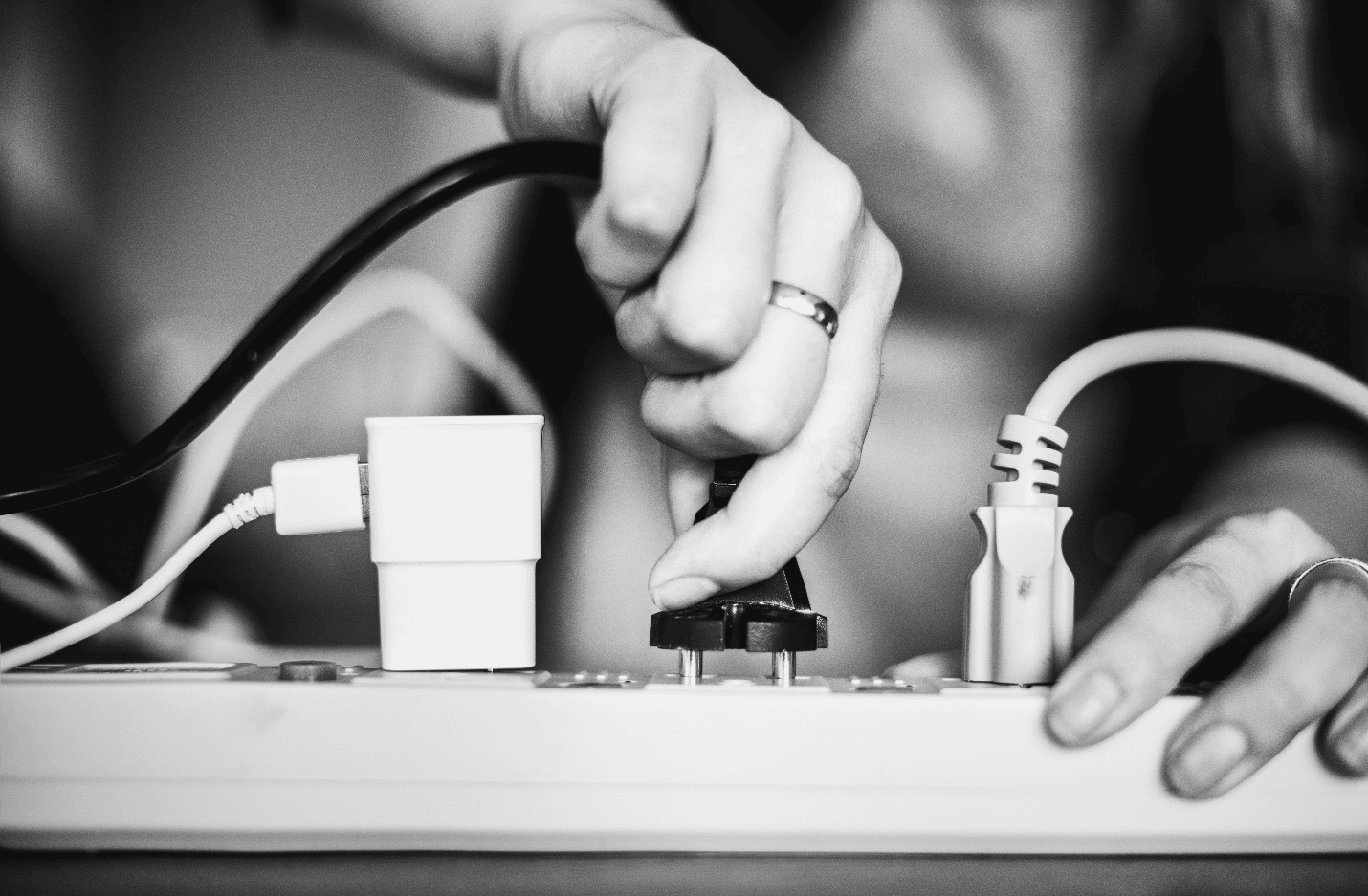

Install the switch box

Once done with the trench, it is time to install the sub-panel or switch, depending on the circuit of choice. You can install the switch on the inside or outside of the shed. If outside, ensure it is rated for outdoor use.

Run your conduit

You’ll need to start from where the main power source is. Ensure to provide a weatherproof exit before running it through the trench. Avoid using an indoor wire and then switching to an exterior wire, as this can cause overloading near the main switch.

Pull the wire

Once the conduit reaches the shed, use an electrician’s fishing tape to pull the wire. Feed the tape through the end without the wire. When it gets to the other end, attach it to the wire. Pull the tape. It might take some persuasion, but it will come.

Connect the circuit to the switch and the main box

Ideally, the main panel will have a breaker dedicated to the shed. So, this is the place you’ll determine the power fed to the shed. For example, if you need 60A, you’ll install a 60A breaker. Also, ensure to use the right wire to avoid overloading. Ensure to shut off power when installing the breaker.

Wire your shed

Once you have installed the switch or sub-panel, you can wire the shed. Ideally, you should use a 12/2 wire for a 20V breaker and a 14/2 wire for a 15A. Ensure to use wire staples as they help to keep the wiring flush in the middle of the studs. You can then use GCFI breakers to make receptacles GCFI.

Consult an electrician

Once you are done wiring the shed, call an electrician to ensure everything is working properly. The electrician will look for any faults and offer solutions. After this, an inspector will perform the final analysis.

Final thoughts

As you can see, running power to your shed is not a complicated job. All you need are the right tools and following the above procedure. Be sure to consider the voltage and amps load to avoid overloading once you start using the shed. Tercero aids in how to run electricity to a shed at an affordable price; call us, and let’s discuss your project.